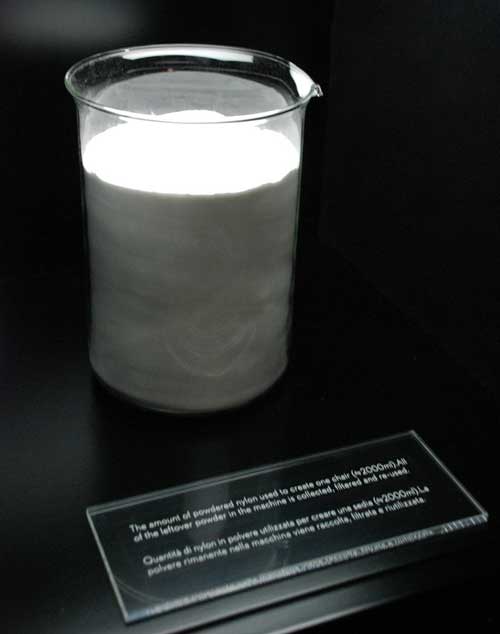

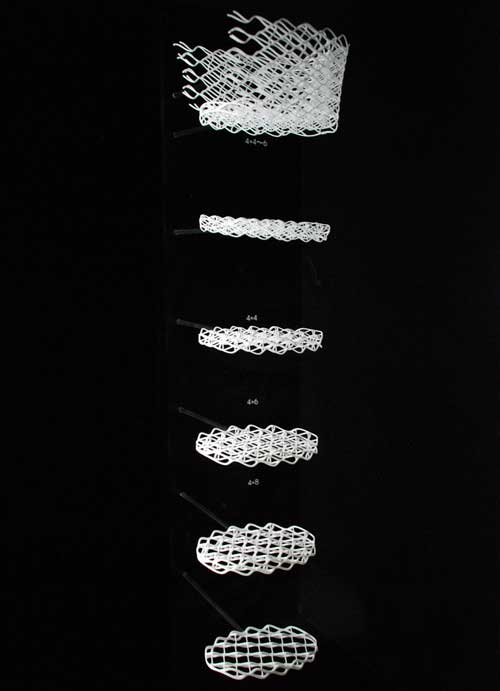

A the Lexus installation at the Salone del Mobile there was an interesting installation about generation of mesh structures which provided hints for their eventual re-generation and re-use. The chair above was manufactured using a 3D printer from 2kg of fused Nylon powder. As part of the exhibition a series of models depicted how the surprisingly sturdy seat’s form was derived from the molecular structure of a crystal molecule (below). In the last case was displayed the raw material from which the entire chair was molded, in a glass beaker (bottom), suggesting that the mesh structure is an effective way to use a single material efficiently for a variety of applications and leave it in a state that can be cleanly re-fused for a completely different, later use.