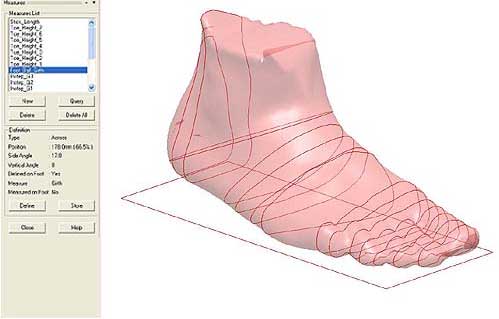

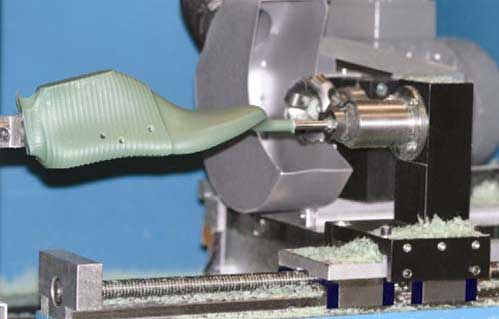

mass customization is only slowly gaining ground in industries such as automobiles, and usually only with cosmetic choices like the color of seats. a number of shoe manufacturers have interfaces for customers to select colors and styles, but use standard forms that compromise fit. unfortunately not all countries have craftspeople cabable of custom shoe-making, in fact the united states completely lost its shoe production capacity when industry decided to out-source all production fifteen years ago. today one US company – otabo – is attempting another solution: automating the shoe-making process for high-quality shoes through sophisticated software. from top, a laser scan of each of your feet is used to sculpt a custom last and generate designs which are cut by numerically-controlled cutters and stitched by robotic sewing machines. even the shank is custom-fabricated using fiberglass, which is stronger and lighter than steel. impressive, although it makes me wonder if cobblers couldn’t do the same with a much cheaper investment.

via sergio dulio

2 Trackbacks

[…] for them. it has the spirit of transparency of programs like dole’s organic labels, with the mass customization you would expect from local experts, all the while supporting elderly people to make an independent […]

[…] for them. It has the spirit of transparency of programs like dole’s organic labels, with the mass customization you would expect from local experts, all the while supporting elderly people to make an independent […]